FMB has over 20 years of experience in building X-ray beam position monitors (XBPMs), which are extensively utilized at many synchrotrons worldwide.

In order to gain a complete picture of the beam characteristics, precise image formation about the size, position, and shape of the beam is required.  XBPMs manufactured by FMB offer high-precision monitoring of the photon beam position, enabling an on-line determination of the horizontal and vertical beam position with micrometer accuracy.

XBPMs manufactured by FMB offer high-precision monitoring of the photon beam position, enabling an on-line determination of the horizontal and vertical beam position with micrometer accuracy.

The FMB XBPM design is a joint development by Dr. Karsten Holldack (HZB) and FMB Berlin.

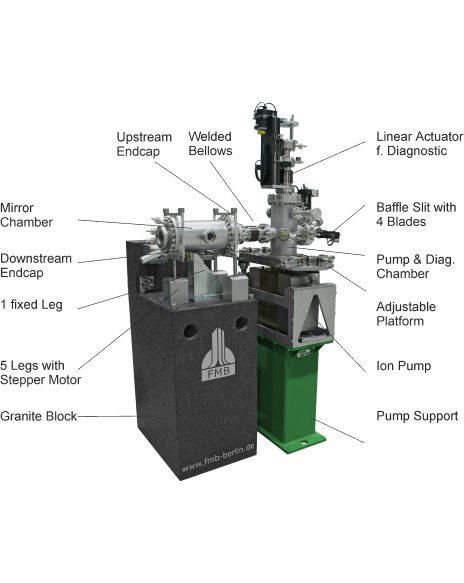

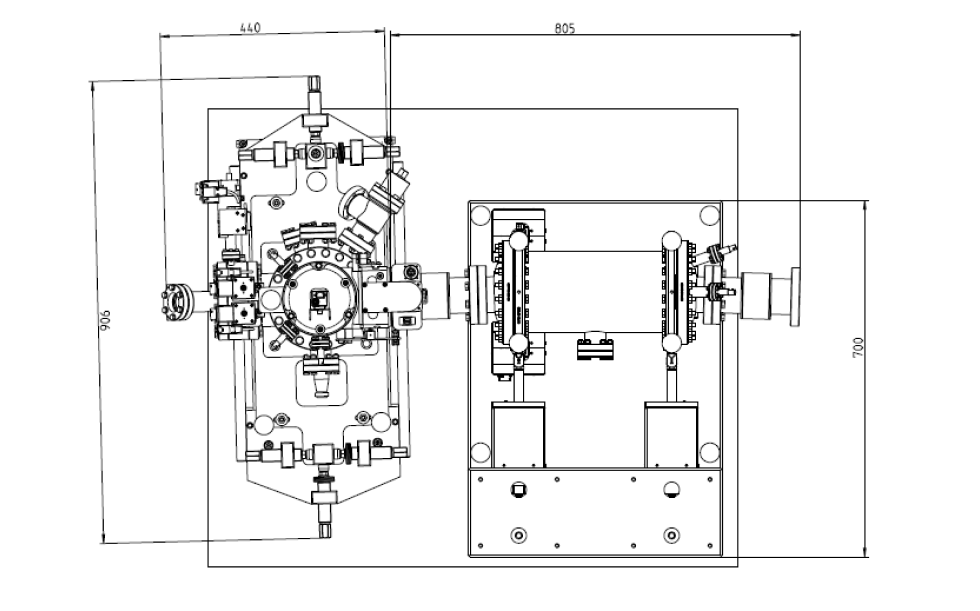

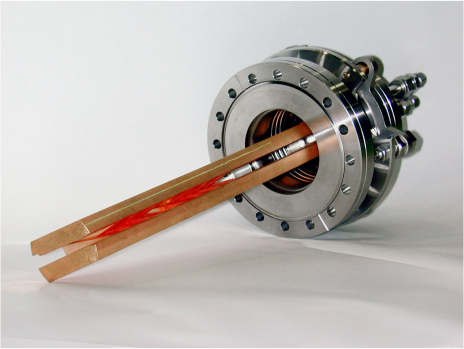

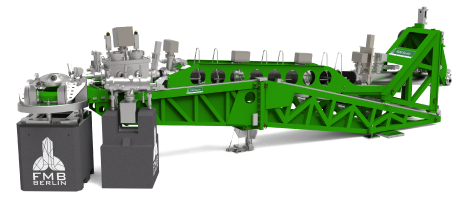

A typical FMB XBPM system includes an XBPM insert, a vacuum chamber, an X-Z precision motorized stage, and a steel column support. The four blades within the XBPM insert are arranged symmetrically on a virtual X-letter with the photon beam axis passing through its center. The blades are typically made of tungsten and cooled using heat-conducting ceramics to resist the thermal load generated by the radiation. With this configuration, the operator can also scan the beam center’s off-axis radiation on-line.

The size and geometry of the blades are customized to match the specific beam characteristics at the installation site of the beam position monitor to achieve maximum photocurrent yield at maximum sensitivity.

The technical data below is based on our standard FMB XBPM unit system. We also offer customized XBPM units upon request. For inquiries, please contact us.

| Type | 5+1 LegsMirror Unit | |||

|---|---|---|---|---|

| Common Parameters | ||||

| Common Parameters | Range | Full-step-resolution | ||

| Reflection angle (horizontal/side-bouncing): | ≥175° | |||

| Lateral translation (lateral leg drives): | ±5 mm | 0.025 μm | ||

| Height translation (vertical leg drives) | ±5 mm | 0.025 μm | ||

| Variable parameters | Long version | Standard version | Thick version | Short version |

| Blade material / Thickness: | Tungsten / 0.2 mm | |||

| Aperture / Blade opening, Blade angle: | Suggested by FMB, dependent on beam specifications at the installation position |

FMB has over 20 years of experience in building X-ray beam position monitors (XBPMs), which are extensively utilized at many synchrotrons worldwide.

In order to gain a complete picture of the beam characteristics, precise image formation about the size, position, and shape of the beam is required.

XBPMs manufactured by FMB offer high-precision monitoring of the photon beam position, enabling an on-line determination of the horizontal and vertical beam position with micrometer accuracy.

The FMB XBPM design is a joint development by Dr. Karsten Holldack (HZB) and FMB Berlin.

A typical FMB XBPM system includes an XBPM insert, a vacuum chamber, an X-Z precision motorized stage, and a steel column support. The four blades within the XBPM insert are arranged symmetrically on a virtual X-letter with the photon beam axis passing through its center. The blades are typically made of tungsten and cooled using heat-conducting ceramics to resist the thermal load generated by the radiation. With this configuration, the operator can also scan the beam center’s off-axis radiation on-line.

The size and geometry of the blades are customized to match the specific beam characteristics at the installation site of the beam position monitor to achieve maximum photocurrent yield at maximum sensitivity.

FMB has over 20 years of experience in building X-ray beam position monitors (XBPMs), which are extensively utilized at many synchrotrons worldwide.

In order to gain a complete picture of the beam characteristics, precise image formation about the size, position, and shape of the beam is required.

XBPMs manufactured by FMB offer high-precision monitoring of the photon beam position, enabling an on-line determination of the horizontal and vertical beam position with micrometer accuracy.

The FMB XBPM design is a joint development by Dr. Karsten Holldack (HZB) and FMB Berlin.

A typical FMB XBPM system includes an XBPM insert, a vacuum chamber, an X-Z precision motorized stage, and a steel column support. The four blades within the XBPM insert are arranged symmetrically on a virtual X-letter with the photon beam axis passing through its center. The blades are typically made of tungsten and cooled using heat-conducting ceramics to resist the thermal load generated by the radiation. With this configuration, the operator can also scan the beam center’s off-axis radiation on-line.

The size and geometry of the blades are customized to match the specific beam characteristics at the installation site of the beam position monitor to achieve maximum photocurrent yield at maximum sensitivity.

| Project | Customer | Year | Project Number | Details |

|---|---|---|---|---|

| Upgrading 10 single XBPMs (ongoing project) | SLS | 2023 | 2023 0325 | 2023 0325 |

| 1 single XBPM within the scope of frontend for the beamline BL31-FAXTOR (source: MPW-50 (Multi-Pole Wiggler)) | ALBA | 2020 | 2020 0367 |

© Copyright 2024 FMB Feinwerk- und Messtechnik GmbH All rights reserved